Special Medical Needles and Stainless Steel Capillaries present unique engineering challenges due to their small dimensions and performance expectations. Minor variations can influence system behavior, making process control a central concern throughout production.

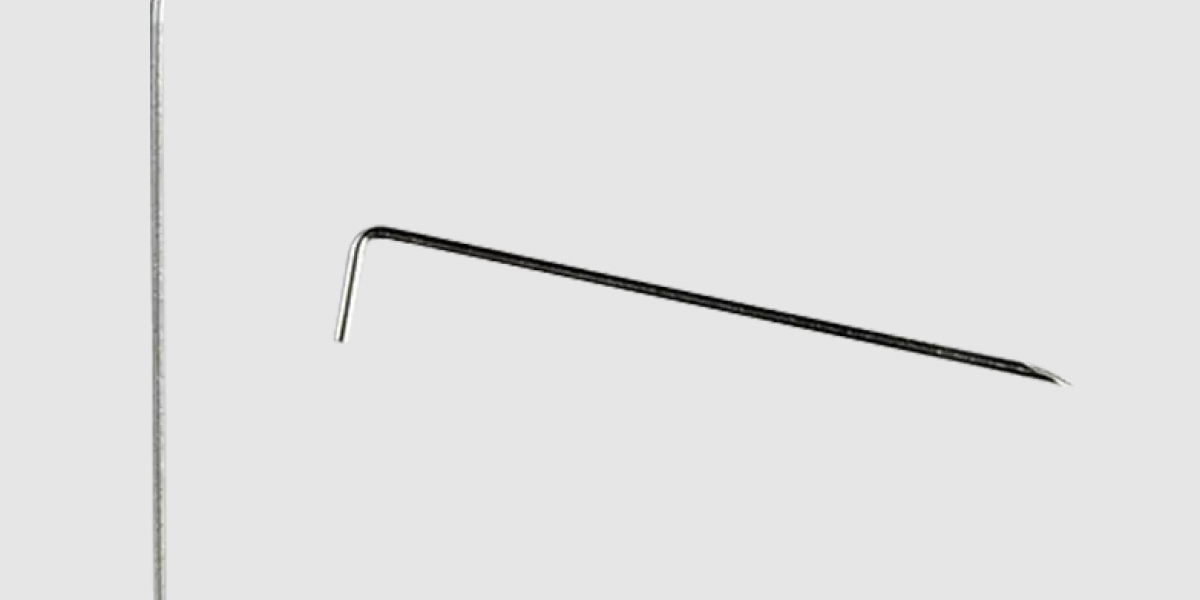

Dimensional accuracy remains a primary focus. Needle outer diameter, wall thickness, and tip alignment must remain within specified ranges to ensure predictable interaction. Capillary internal diameter consistency is equally critical, particularly for applications involving calibrated fluid delivery.

Manufacturing equipment is selected and maintained to support tight tolerances. Tool wear, temperature variation, and material batch differences are monitored to reduce drift. Operators receive training to recognize early signs of deviation and apply corrective actions.

Stainless steel properties influence forming behavior. Work hardening, elasticity, and surface response are managed through controlled annealing and finishing processes. These steps help maintain balance between strength and formability, supporting reliable downstream use.

Integration into medical assemblies requires compatibility with connectors, housings, and sealing elements. Manufacturers consider these interfaces during design and production, reducing assembly challenges for device producers. This alignment supports efficient manufacturing at the system level.

Documentation accompanies each production batch. Material certificates, inspection records, and process data provide transparency and support regulatory requirements. These records assist customers during audits and internal quality reviews.

Ongoing improvement efforts focus on yield stability and process repeatability. Small refinements in tooling or inspection methods can enhance long-term performance without altering product design. Such incremental development supports sustained supply relationships.