In today’s competitive manufacturing landscape, Mold Customization plays an essential role in delivering precision parts tailored to specific product requirements. However, the value of customized molds extends far beyond their initial production. Effective after-sales service, proactive maintenance, and timely repair are crucial components that ensure molds continue to perform reliably throughout their lifecycle. Understanding how to maintain and extend the lifespan of molds created through Mold Customization is vital for manufacturers seeking to maximize return on investment and maintain production efficiency.

Maintenance Methods for Customized Molds

Proper maintenance is the foundation of mold longevity following Mold Customization. Regular cleaning is among the simplest yet most important tasks. Residual materials, lubricants, and contaminants must be thoroughly removed after each production run to prevent corrosion or surface damage. Using appropriate solvents and soft brushes helps preserve the mold’s surface integrity without causing abrasion.

Lubrication is another key factor in mold care. Customized molds often include moving parts such as slides, lifters, and ejector pins. These components require consistent lubrication to reduce friction and wear. Applying the right type of lubricant, as recommended by mold manufacturers, ensures smooth operation and prevents premature failure.

Routine inspection is essential in identifying early signs of wear or damage. During scheduled maintenance, technicians should examine critical areas such as cavities, cores, and parting lines for cracks, deformation, or erosion. Early detection enables swift corrective measures, reducing downtime and preventing costly production interruptions.

Repair and Improvement Services for Customized Molds

Despite careful maintenance, molds from Mold Customization inevitably experience wear and tear due to high operational demands. Timely repair services are therefore indispensable. Repair work often involves re-polishing worn surfaces, replacing damaged inserts, or welding and machining areas affected by cracks or corrosion.

Advanced repair techniques, including laser welding and precision machining, allow customized molds to regain their original accuracy and finish. These methods help restore molds without the need for costly complete replacements, thereby offering economic benefits.

In addition to repair, improvement services are an important part of the after-sales support for Mold Customization. As production requirements evolve, molds can be modified to enhance performance or adapt to new materials. Such improvements may include redesigning cooling channels for better temperature control or altering venting systems to reduce cycle times. Working closely with mold manufacturers to implement these upgrades can significantly improve product quality and manufacturing efficiency.

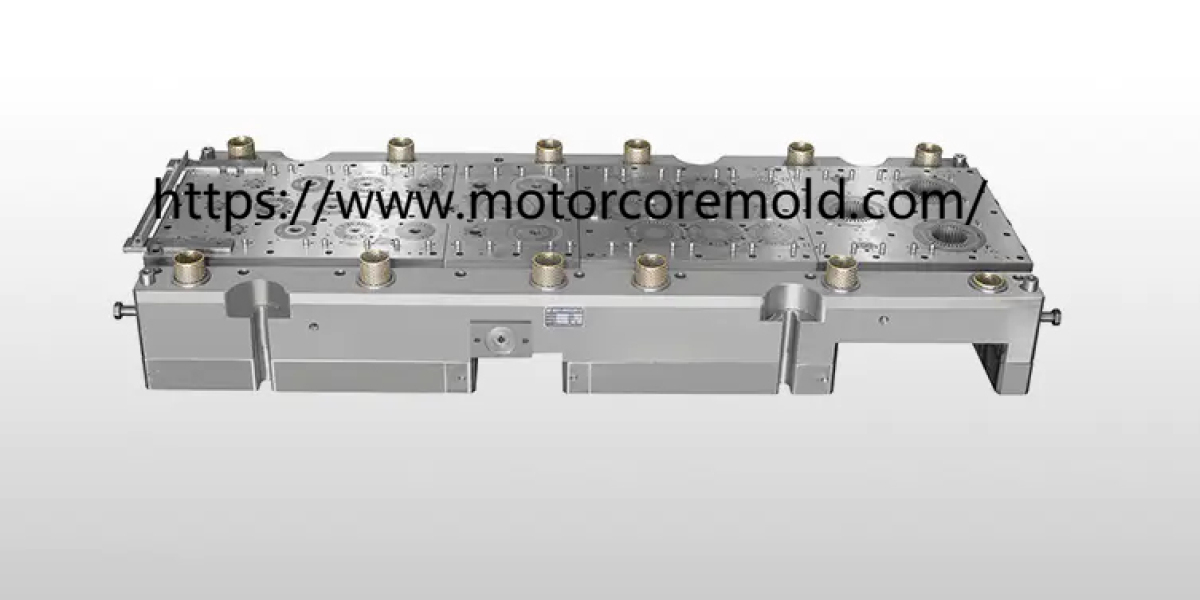

| Comprehensive life: | ≥160 million punches |

| Blade die life: | ≥5 million strokes/0.1mm |

| Mold structure: | Three-plate mold base + ball guide |

| Effective cutting edge height: | ≥8mm |

| Blade material: | DJ40 |

| Grooved die form: | Punch grooved die, slow wire finishing, the punch is polished using a special process to remove the oxidation layer |

| Guide parts: | Precision + high hardness |

| Blanking speed during running-in period: | 80-280 punches/minute |

| Blanking speed: | 280-300 punches/minute |

| Concentricity: | ≦0.05mm |

| Protection device: | Equipped with misfeed protection device |

| Punching burr: | ≦0.05mm |

| Riveting force: | 30N |

| Safety device: | Misfeed detection + equal height limit column |

| Product output form: | Conveyor belt Rotor control device Chute control device |

| Plate control device: | Cylinder |

| Mold base material: | Upper and lower mold seats P20. middle unloading seat P20. the second and fourth levels are made on the same set of molds and are interchangeable during production. The shaft hole can be used for three interchangeable pumping plates. |

| Spare parts provided: | 30% of wearing parts |

| Internal plate material: | Cr12MOV |