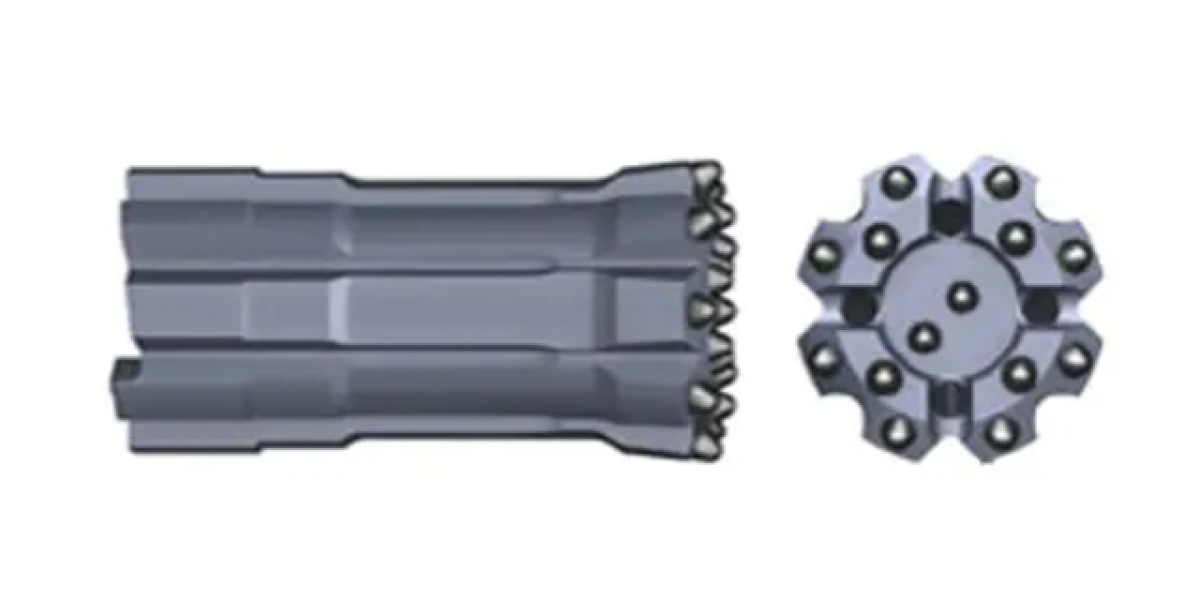

In modern drilling projects, the combination of a DTH Hammer and a DTH Bit plays a crucial role in achieving effective penetration through hard rock formations. The DTH Hammer acts as a pneumatic tool that delivers rapid percussive energy directly to the drilling face, making the process faster compared to conventional rotary drilling.

The DTH Bit, attached at the end of the hammer, is responsible for breaking the rock with its specially designed cutting edges. The coordination between these two tools ensures consistent drilling performance in various mining, construction, and water well applications.

One of the key advantages of using a DTH Hammer with its matching bit is the ability to maintain drilling accuracy even in challenging geological conditions. Additionally, the modular nature of these tools allows operators to switch bits depending on the rock hardness and drilling depth requirements.

Understanding the specific function and interaction of the DTH Hammer and DTH Bit helps operators select the right equipment configuration. Proper maintenance and timely replacement of bits can also extend the operational life of the hammer, reducing downtime and enhancing overall productivity.